| Output Quantity | 250ml – 1000ml |

| Output | 1500~2000 packs/hr. |

| Filler Accuracy | ± 3 gm |

| Westage | 1~2 Meters at start up |

| Pack / Quantity Range Min. Bag size (W x L) approx Max. Bag size (W x L) approx |

100 mm x 135 mm 225 mm x 350 mm |

| Packaging Material | Co-extruded 3 or 5 Layer PE Based or Laminated 65 to 120 microns |

| Film Reel | Core dia 76 mm & Reel diameter 300 mm max. Width 400mm~690mm |

| Electrical Requirement | |

| Input Supply | 208/240 V, 3 phase 60 Hz, 3 ph + N + G |

| Connected Load | 5.5 KVA |

| Peak Power Rating | 5 KW |

| Cooling Water | |

| Flow Rate | 200 ltr/hr |

| Temperature Range | 6° to 10°C maintained |

| Minimum Pressure | 6 bar |

| Machine Dimensions(W x D x H) approx. | 850 mm x 700 mm 2760 mm |

| Weight | 700 kgs (Net) |

| Suitable for Packing | Pasteurized milk, cream, edible oil, butter oil pasteurized fruit pulp and water. |

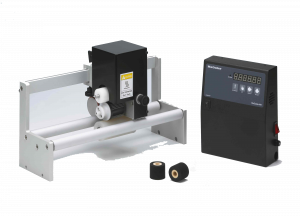

Our machines can be equipped with different types of date coding devices such as ink jet printers, thermal date coding devices etc. The date coding device is used to print precise, easy-to-read and indelible date codes and batch codes that are not only critical for many industries but are also mandatory by many Governments around the world. These devices have the ability to print use-by dates, best-before dates and batch codes.