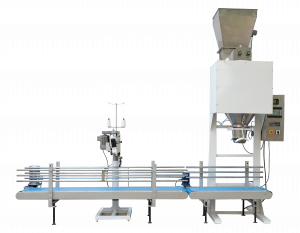

The sewing machine works hand in hand with our bulk machines where we have installed numerous such machines for closing of different bag types. Our sewing machines are all manufactured by reputable original equipment manufacturers (OEM) which are synchronized and integrated with our (Solidio-BK) bulk machine. The sewing machine manufactured are all durable and are being used to close a variety of bag types such as polyethelene (PE), woven and aminated woven polypropylene (PP). We offer our clients a range of sewing machines such as handheld portable bag closers to heavy production synchronous sewing systems.

| Output Quantity | 5kg – 20 kg 10kg-50 kg |

| Output | 10 – 15 bags/min 06-12 bags/min |

| Filler Accuracy | ± 0.05-0.25 % |

| Pack / Quantity Range Min. Bag size (W x L) approx Max. Bag size (W x L) approx |

305 mm x 356 mm 533 mm x 890 mm |

| Packaging Material | Co-extruded 3 or 5 Layer PE Based or Laminated, Metalize, Aluminum Foil, Polypropylene woven bag, Jute bag, Cotton Bag, Paper Bag, China fusing, etc |

| Electrical Requirement | |

| Input Supply | 380 V AC, 50 Hz, 3 ph + N + G |

| Connected Load | 2.5 KVA |

| Peak Power Rating | 2.35 KW |

| Air Requirement | |

| Air Pressure | 6 bar Constant dry air |

| Air consumption | 800 ltr/mnt |

| Machine Dimensions along with conveyor (W x D x H) approx. |

3550 mm x 1525 mm 2970 mm (Depend on customized requirements.) |

| Weight | 600 kgs (Net) |

| Suitable for Packing | Potato Chips, Snacks ,Rice, Macaronis Beans, Pasta, Dry Fruits, Vermicelli, Candies & Confectionery products as well as all kinds of light weight products. |